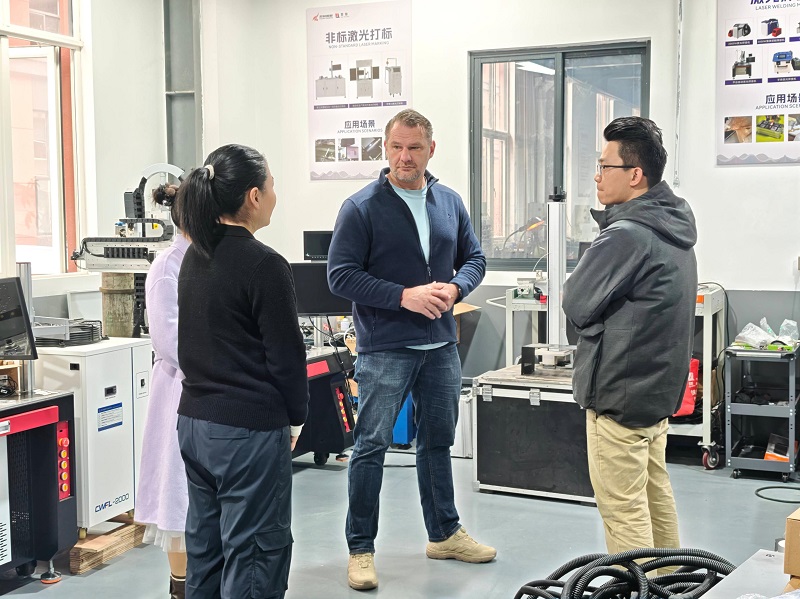

On December 2, 2025, a delegation from a well-known Belgian industrial group arrived in Chongqing for a two-day in-depth inspection of Chongqing Chuke Intelligent Machinery Equipment Co., Ltd. (hereinafter referred to as "Chuke Intelligent"). This visit focused on the technical adaptability and localization services of high-end equipment such as laser marking, welding, and cleaning. Both sides reached several consensuses on cooperation in areas such as new energy projects in Africa and precision manufacturing in Europe, marking a new stage of intelligent and green cooperation between China and Belgium in industrial equipment.

In Chuke Intelligent's modern showroom, the Belgian client focused on experiencing its core product—the 50W

Fiber Laser Marking Machine. This equipment, through a dynamic focusing system and intelligent closed-loop control algorithm, achieves a 0.1 mm depth marking on aluminum alloy specimens, with an error controlled within ±0.02 mm, smooth edges without burrs, and a depth consistency of 99.8%. After on-site testing, the client's technical manager stated, "We compared our equipment with those from German and Swiss brands. Chuke Intelligent's dynamic spot compensation technology can automatically correct minute undulations on metal surfaces, which is crucial for anti-counterfeiting and traceability of aerospace components."

Furthermore, Chuke Intelligent's automated laser welding production line attracted significant interest from the client. This line integrates robotic welding, visual inspection, and data traceability systems, achieving 80 high-efficiency stamping operations per minute with an error rate of less than 0.05 millimeters. It is already serving the global supply chain of a Russian automotive group. "European manufacturing is facing pressure from energy transition, and Chuke Intelligent's equipment excels in energy saving and efficiency. For example, its

Laser Welding Machine reduces energy consumption by 60% compared to traditional processes, which complies with EU carbon tariff requirements," emphasized the client's purchasing director.

To address the extreme environment application needs of a Belgian client, Chuke Intelligent demonstrated several customized devices on-site: A

Laser Cleaning Machine: operating in extremely cold environments down to -40°C, this equipment removes metal oxides five times more efficiently using a non-contact laser beam, with no wastewater discharge; this has been verified through field testing at a factory in Siberia. A high-temperature

Marking Machine: employing tungsten alloy needles and inert gas protection technology, it can operate stably at 800°C, meeting the high-temperature component marking requirements of the metallurgical industry. A

Handheld Laser Welding Machine: flexibly adaptable to the confined spaces of older European factories, it supports multi-language operating systems, reducing technical adaptation costs.

“Chuke Intelligent’s global service network is impressive,” a customer representative noted. “Their plan to establish an overseas service center in Belgium, equipped with a 48-hour emergency response team, aligns perfectly with our ‘zero downtime’ production goal.”

Chuke Intelligent Chairman Xiao Renmin revealed during the exchange that the company is accelerating its expansion in the European market, developing three solutions to address the pain points of the local manufacturing industry: Intelligent Marking System V4.0: Equipped with an AI visual recognition module, it can adaptively mark complex curved surfaces with an error rate of less than 0.01 mm; Green Laser Welding Production Line: By using beam shaping technology to reduce the heat-affected zone, welding deformation is reduced by 75% compared to traditional processes; Modular

Laser Cleaning Station: Supports rapid mold changeover and cloud data management, saving 30% on maintenance costs per unit.

Chuke Intelligent’s products have covered more than 50 countries and regions worldwide. In the first half of 2025, overseas orders increased by 120% year-on-year, with its laser cleaning machines achieving a market share exceeding 15% in Europe. This visit from the Belgian customer further solidified its industry position as a “benchmark enterprise for Chinese laser equipment exports.”

At the conclusion of the visit, both parties signed a strategic cooperation agreement. Chuke Intelligent will participate in the construction of the identification system for Belgium's national new energy project and provide a full-chain service from equipment supply to technical training. Xiao Renmin stated, "We are currently building joint laboratories with several universities and colleges, and plan to invest more in R&D over the next three years to promote the deep integration of laser technology with the Internet of Things and digital twins."