On November 2, 2025, Chongqing Chuke Intelligent Machinery Equipment Co., Ltd. welcomed a special visitor—a representative from a well-known domestic glass products company with annual sales exceeding 450 million yuan. The company brought large-capacity perfume bottle samples to Chuke Intelligent's modern factory, witnessed the

UV Laser Marking Machine complete a high-precision drilling test, and signed a million-yuan equipment purchase agreement on the spot, marking the beginning of a deep strategic cooperation between the two parties in the field of high-end glass processing.

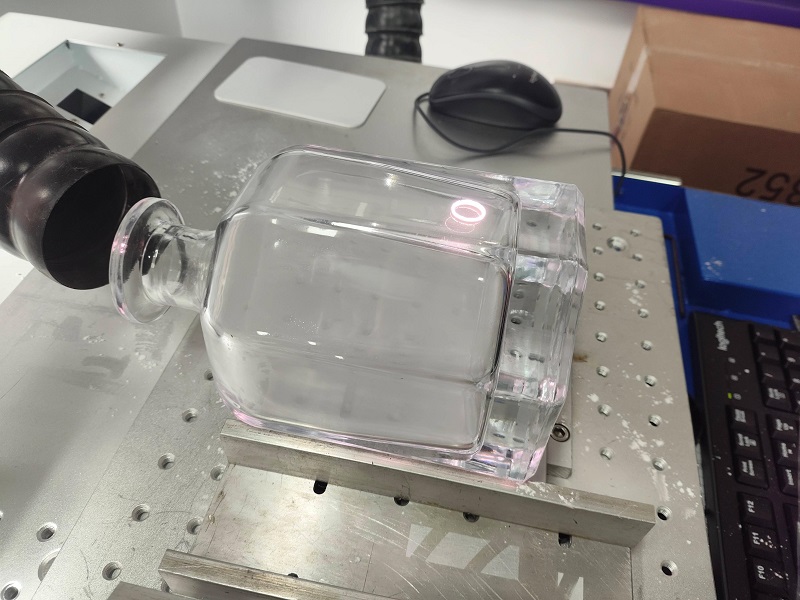

The perfume bottle sample tested was a custom design for an international luxury brand. The bottle body is made of high-strength crystal glass with a wall thickness of 8 mm. A precision through-hole with a diameter of 2 mm needs to be machined at a specific location on the bottle body for connecting a scent testing device in stores. Traditional mechanical drilling processes are prone to problems such as bottle breakage and edge burrs, while chemical etching faces environmental compliance risks. The client had previously attempted this method multiple times without success.

To meet the client's needs, the Chuke Intelligent Technology team utilized a third-generation ultraviolet

Laser Marking Machine (CK-UV-3W) for on-site sample making. This equipment features a 355nm wavelength ultraviolet cold light source and uses third-order intracavity frequency doubling technology to compress the focused spot diameter to 15 micrometers. Combined with a 0.1mm-level dynamic spot adjustment system, it achieves uniform energy distribution on the curved surface of the bottle. After 30 minutes of precise operation, the sample bottle successfully completed the drilling test: the hole diameter error was controlled within ±0.02 mm, the heat-affected zone of the bottle wall was less than 0.05 mm, and the surface roughness Ra ≤ 0.3 micrometers, fully meeting the stringent precision requirements of luxury goods.

"The yield rate of traditional processes is less than 60%, while Chuke Intelligent's laser solution raises this figure to 99.2%," the client's technical director remarked during sample inspection. "More importantly, the non-contact processing completely eliminates the risk of hidden cracks in the bottle, which is crucial for perfume bottles worth hundreds of yuan."

During the testing process, Chuke Intelligent's AI visual positioning system became another major highlight. This system, utilizing deep learning algorithms, can automatically identify the 3D contours of bottles of different sizes, achieving a positioning accuracy of 0.01 millimeters even on irregularly shaped curved surfaces. In simulated mixed-line production tests, the equipment successfully integrated with the customer's existing six bottle types, reducing changeover time from two hours using traditional methods to eight minutes.

"Our intelligent production line under construction needs to handle over 20 bottle types simultaneously, and Chuke Intelligent's flexible solution perfectly matches our requirements," revealed the customer's production manager. The purchased laser equipment will be directly deployed in their intelligent factory in Suzhou, seamlessly integrating with the AGV logistics system and MES production management system, expected to triple the single-line capacity.

As a national high-tech enterprise, Chuke Intelligent has formed a complete technology matrix in the field of laser processing. Its

Uv Laser Marking machine series has accumulated 12 invention patents, and its equipment is exported to over 60 countries and regions. In 2024, the company's CK-UV-3W model achieved an annual output value exceeding 8 million yuan per machine and won the "Chongqing Industrial Design Product Gold Award." "Our picosecond-level ultraviolet laser, currently under development, is expected to enter mass production in 2026," said Xiao Renmin, Chairman of Chuke Intelligent, at the signing ceremony. "This new generation of equipment will further increase processing efficiency by 50% and expand into the fields of superhard materials such as ceramics and sapphire, providing Chinese solutions for the global high-end manufacturing industry."