?

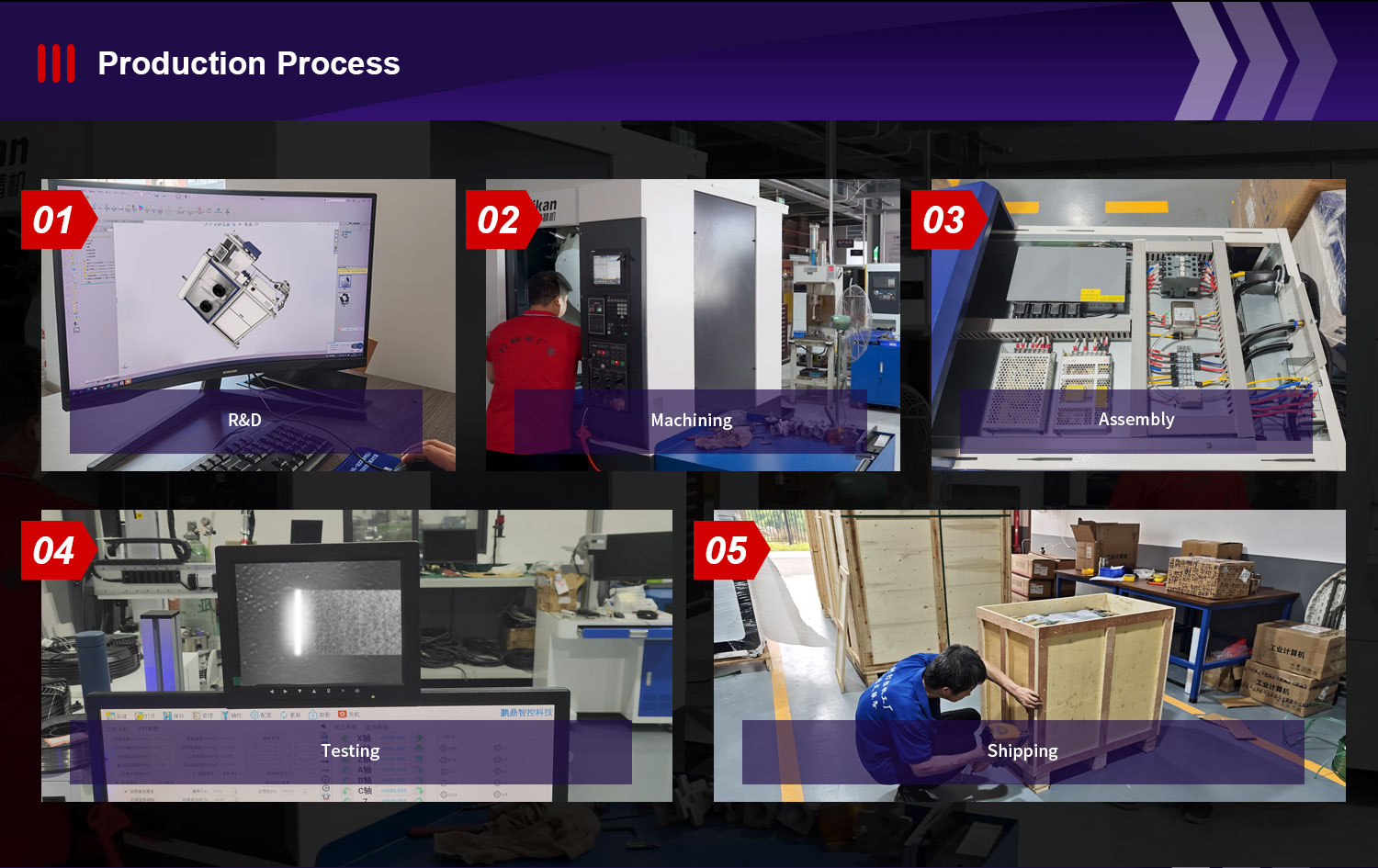

This fully enclosed pneumatic nameplate

Marking Machine is custom-designed for Toyota's cleanroom environment. While meeting Toyota's stringent 6S management and quiet operation requirements, it achieves a quiet marking environment with "zero dust leakage and ≤65 dB(A)". The entire machine features a 2 mm 304 stainless steel laser-welded seamless shell, lined with 8 mm sound-insulating and flame-retardant cotton. The front is equipped with a double-layered 19 mm tempered glass viewing window and a European standard DIN EN 12543 safety electromagnetic lock. The door can only be opened after the compressed air is completely depressurized, the marking head returns to zero, and the safety relay has completed its self-check, completely eliminating the risk of pinching fingers and misoperation.

?

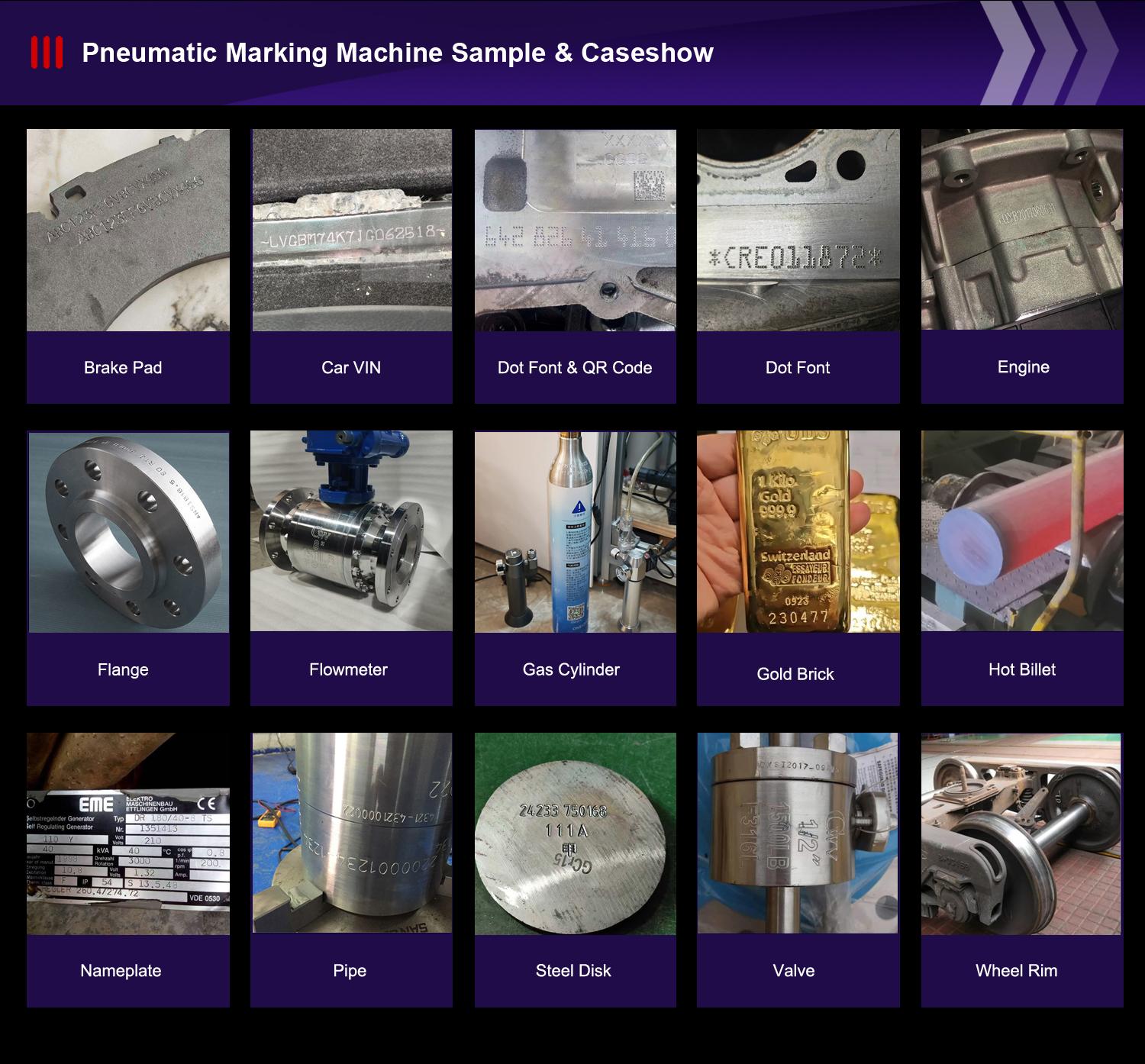

The marking core uses a German-imported FESTO dual-rod low-friction cylinder, paired with a 0.01 mm-level TE Connectivity displacement sensor, enabling the 3 mm carbide nameplate-specific needle to achieve a repeatability accuracy of ±0.05 mm within a 140 mm × 80 mm marking area. The cylinder stroke, pressure, and marking speed can be controlled via a single click using the THORX7 software to access the "Toyota Nameplate" process package. Under 0.5 MPa air pressure and a 1.2 Hz impact frequency, a 17-digit VIN code, QR code, and production serial number with a depth of 0.15 mm can be permanently marked within 6 seconds. The dot matrix is ??smooth, the grooves are uniform, and after 720 hours of salt spray testing, there is no chipping, splashing, or burrs, fully meeting Toyota's TSM0501G corrosion resistance standard.

?

The manual clamp uses a quick-release elbow clamp + adjustable positioning pin structure, allowing for switching between different thicknesses of aluminum, stainless steel, and copper nameplates (0.5 mm–2 mm) within 30 seconds. An RFID chip is embedded in the clamp's base plate; the THORX7 software automatically identifies the clamp model and calls the corresponding marking template, eliminating human error in machine adjustments. The software includes the Toyota-exclusive font "Toyota Gothic 2025," with a character height of 3 mm and a line width of 0.4 mm. Authorized by Toyota's Japanese headquarters font department, it maintains visual consistency with global production lines. It also offers OEM font customization services for Mercedes-Benz ("Daimler Sans") and BMW ("BMW Type Global"), allowing for one-click switching at no extra cost.

?

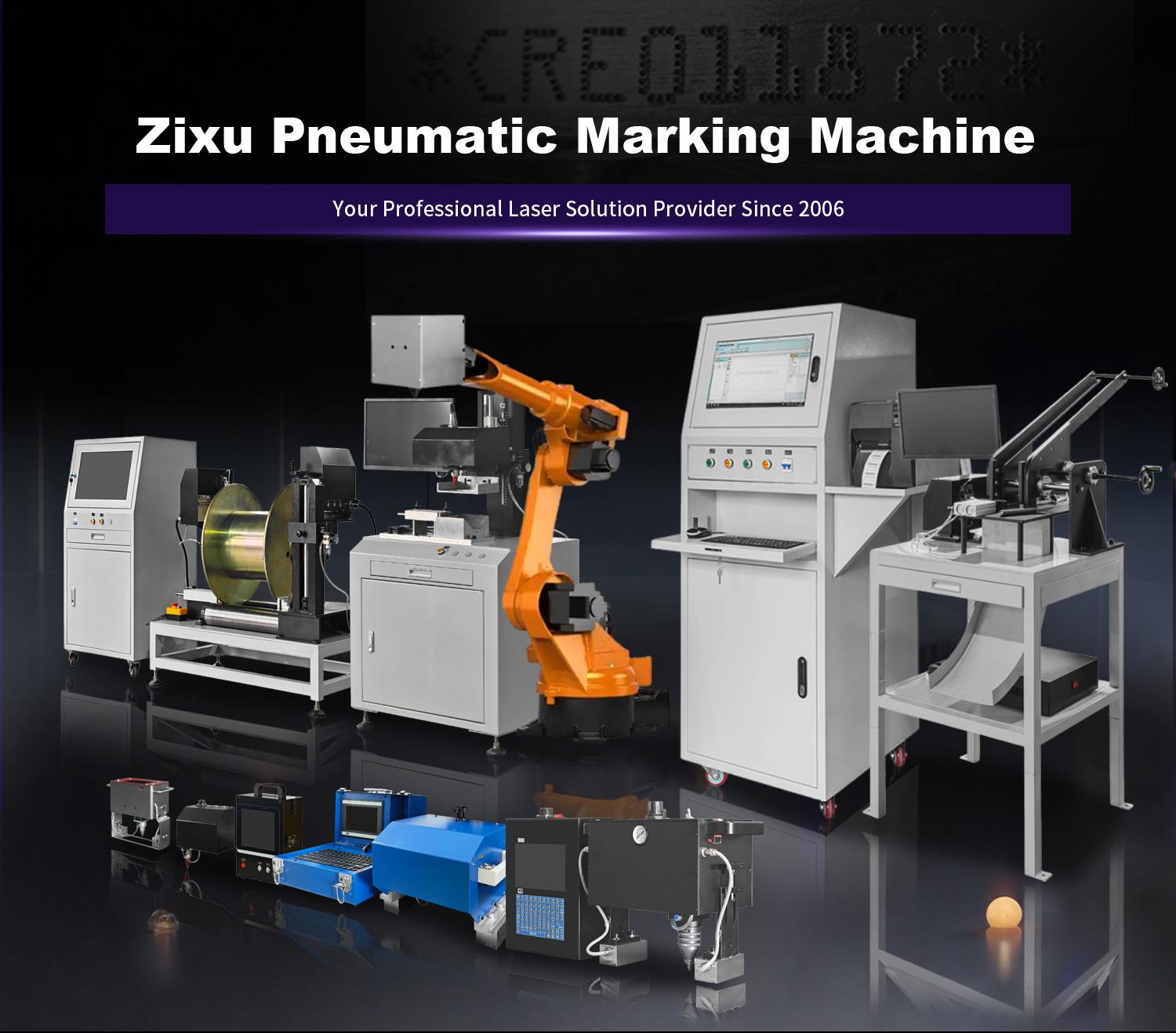

The machine has passed EU CE+RoHS and ISO 13849-1 PLe safety certifications, as well as Toyota's internal EHS audit, with a mean time between failures (MTBF) of ≥20,000 hours. Routine maintenance requires only adding 2 ml of dedicated grease every 2,000 hours via the FESTO self-lubricating system, a process that takes only 5 minutes. Whether in Toyota's global JIT production lines or the cleanrooms of Mercedes-Benz, BMW, and Tesla, this fully enclosed

Pneumatic marking machine—combining the high precision of a

Laser Marking Machine, the depth marking of a

Dot Peen Marking Machine, and the stable power of a Pneumatic Marking Machine—can complete high-quality, traceable marking in just 52 seconds, achieving "zero defects, zero noise, and zero downtime," providing lifelong readable data assurance for subsequent assembly, after-sales service, and recalls.

?